High precision, acid &alkali resistance and easy clean sanitary titanium porous sintered filter plate

Material:Gr1 pure titanium

Size:Customized

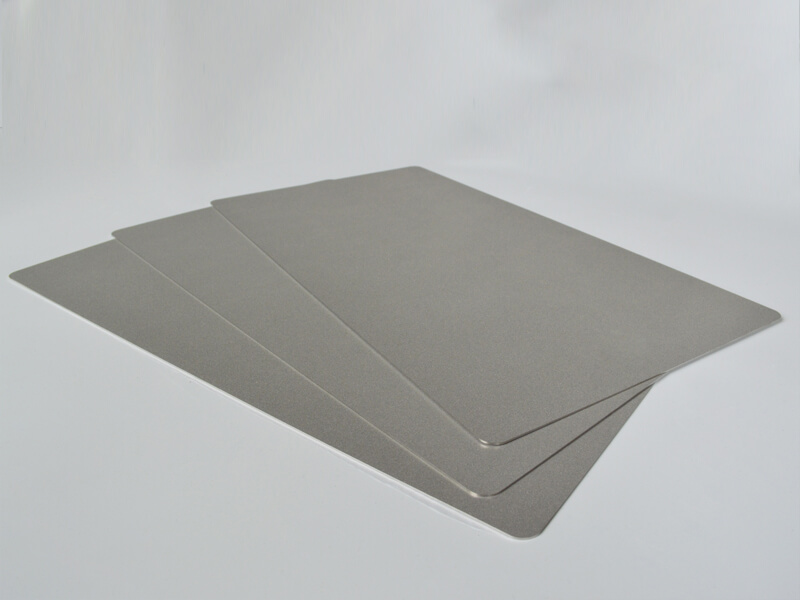

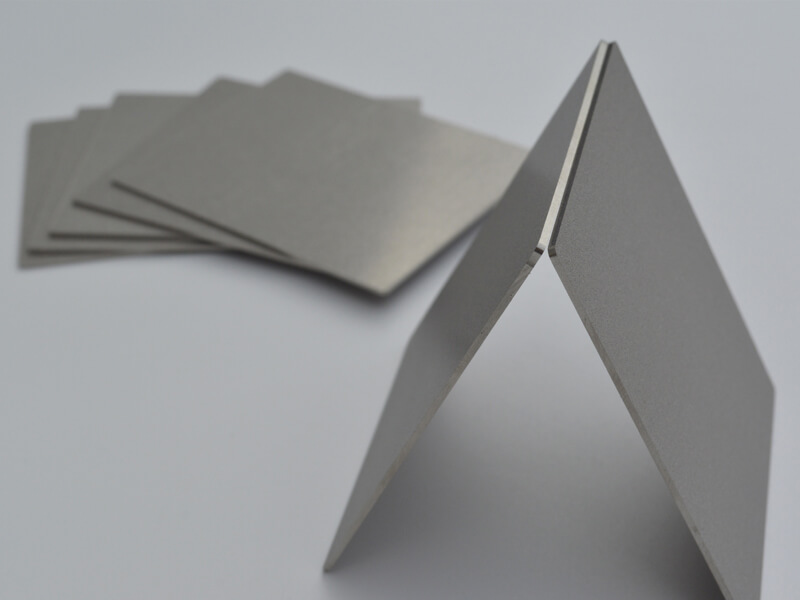

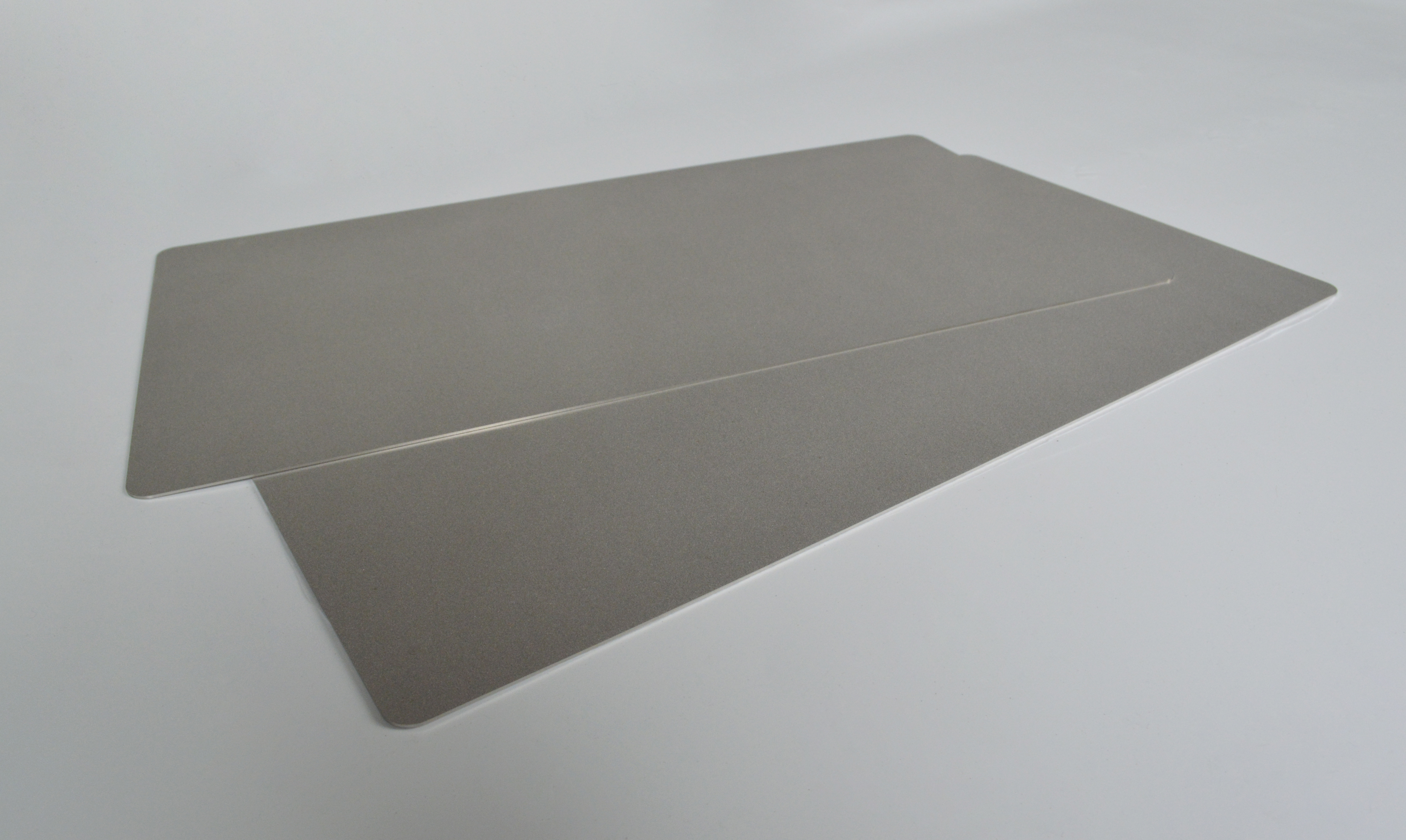

Type:Titanium sintered plate

Application:PEM Fuel cell,Water electrolysis hydrogen, Food and beverage hygienic clarification filtration,Medical implant,fluidized bed,Catalyst filtration,Filtration and Recovery

Titanium sintered porous material is a kind of porous material with high quality spherical and high purity titanium powder as raw material and it is made rigid by forming and sintering at high temperature.

Materials

Filter rating

Porosity

Working pressure

Working temperature

Shape

0A puretitanium powder

5um-80um

25-45%

3-800M³/M²hKPa

2.5MPa

300℃

10-40cm²/cm³

|

Production |

Longth(Dia) |

Wideth(Dia) |

Thickness |

Customized |

|

Sintered porous disc |

Maximum diameter φ800mm |

|

0.5-30mm |

Yes |

|

Sintered porous sheets

|

Max 800mm |

Max 350mm |

0.5-30mm |

Yes |

|

Sintered porous tubes

|

Max of Single 1200mm |

Max diameter φ200mm |

Wall Thickness 2-10mm |

Yes |

6. Strong anti-microbial ability, does not interact with microorganisms.