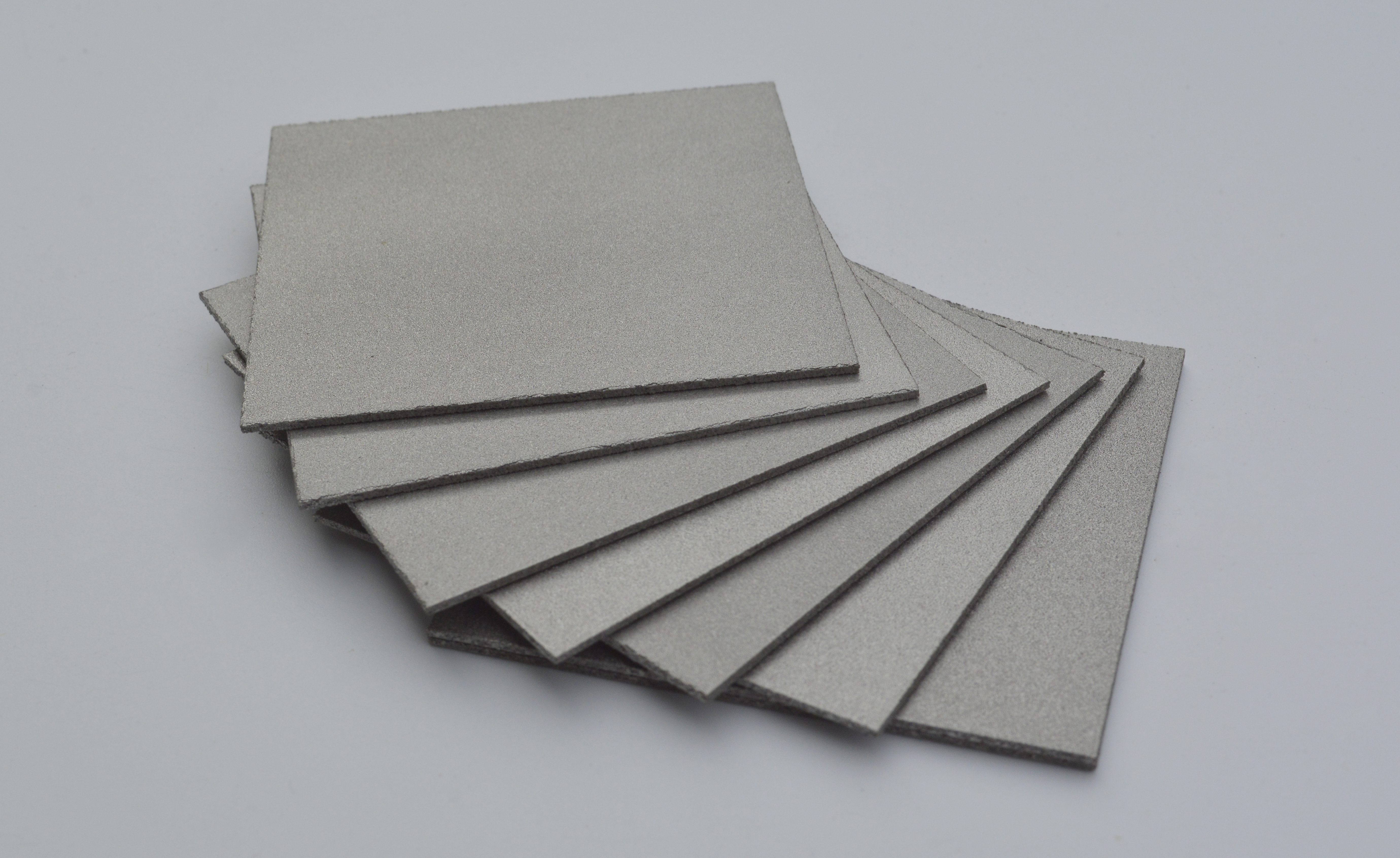

High precision and high temperature resistance metal powder sintered stainless steel porous plate

Material:304 316 316L stainless steel powder

Size:Customized

Type:stainless steel sintered plate

Application:Solid - gas and solid - liquid filtration and purification,Steam filtration, medical food and beverage filtration

Stainless steel metal powder sintered porous material is made of metal or alloy powder by forming and sintering at high temperature and with a rigid structure.

Production Steps: Filtrate-- Isostatic compaction--Vacuum sintering

Advantage: good permeability, pore size, and porosity are controllable, shape stability, high filtration accuracy, wear-proof, good mechanical properties, good thermal conductivity, heat resistance, heat dissipation performance, backflush, and reuse.

|

Materials |

Filter rating |

Porosity |

Penetrability |

Working pressure |

Working temperature |

Shape |

Specific surfac area |

|

stainless steel powder |

0.5um-70um |

25-45% |

3-1300M³/M²hKPa |

3MPa |

600℃ |

Round disc、sheet、tube、round bar、cap |

10-40cm²/cm³ |

|

Production |

Longth(Dia) |

Wideth(Dia) |

Thickness |

Customized |

|

Sintered porous disc |

Maximum diameter φ800mm |

|

0.5-30mm |

Yes |

|

Sintered porous sheets |

Max 800mm |

Max 350mm |

0.5-30mm |

Yes |

|

Sintered porous tubes |

Max of Single 1200mm |

Max diameter φ200mm |

Wall Thickness 2-10mm |

Yes |

Properties of sintered porous stainless steel materials:

1. High-temperature resistance, in normal use under 600 ℃.

2. High mechanical strength, good plasticity, can be machined.

3. Corrosion resistance, oxidation resistance, can be used in nitric acid, sulfuric acid, dilute hydrochloric acid (5%), acetic acid, liquid hydrogen, liquid nitrogen environment.

4. Good molding process, according to customer drawings for processing a molding.

5. High filtration precision and good purification effect.

6. The pores are uniform, the internal structure is stable, and no particles fall off.

7. Good air permeability, easy to back blow cleaning, can be used repeatedly online regeneration.

8. Wear resistance and impact resistance, good mechanical properties.

The application of sintered stainless steel filter materials:

According to its physical and structural characteristics, stainless steel sintered porous materials are mostly used in the fields of noise elimination, filtration and separation, fluid distribution, flow-limiting, capillary core and so on.

1. The chemical raw material production process in addition to impurity filtration, material decarburization filtration, and fine filtration.

2. Ultrafiltration, RO, EDI system security filtration in water treatment.

3. The food and beverage industry finished product clarification filtration.

4. Filtration and recovery of the precious metal catalyst in the petrochemical industry.

5. Precision filtration of liquid raw materials, products and pharmaceutical intermediates in the chemical industry.

6. Reverse osmosis security filtration in the field of water injection filtration.

7. Gas purification of steam, compressed air deoiling purification.

8. Medium purification and flow limitation for pneumatic components, lubricants, fuels, and hydraulic pressure systems.

9. Chemical dye industry of high - temperature decarburization.

Method for cleaning stainless steel sintered porous materials:

1. The decarbonization filter elements in the pharmaceutical and chemical industries are mainly back blown and backwash, and the ultrasonic cleaning is the best.

2. The filter elements of the water industry are mainly rinsed with a 5% concentration of nitric acid.

3. According to the chemical properties of the filtered impurities, the filter elements of the original liquid shall be respectively soaked in pickling (5% nitric acid) or alkaline washing (3-5% sodium hydroxide) and then washed with ultrasonic cleaning.